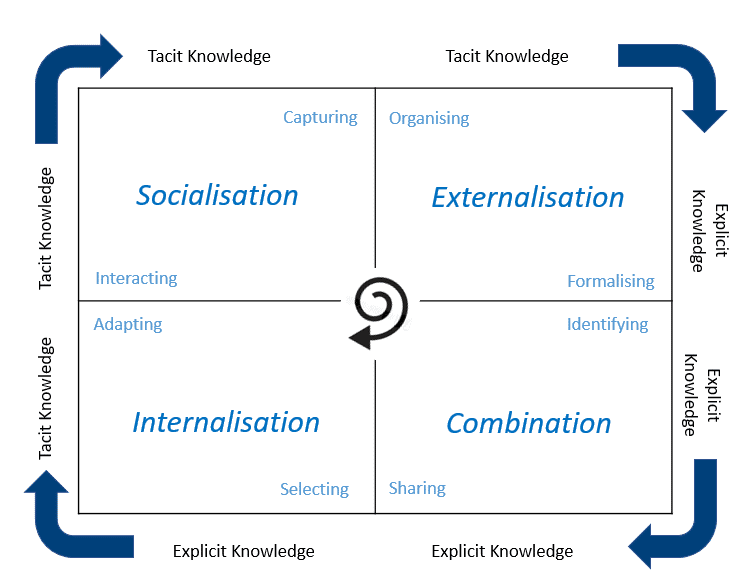

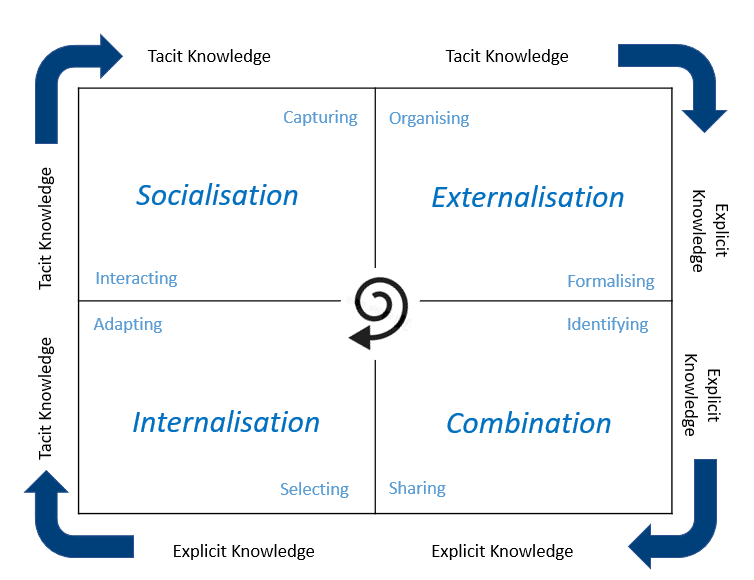

85 SECI

Adapted from Nomura and Kametsu (1999), p.64.

SECI stands for:

Socialisation

Externalisation

Combination

Internalisation

Increasingly human factors and the people side of Lean have become part of the story. Respect for people and Kaizen, a Japanese concept of continuous improvement through incremental changes based on constant learning, are foundations of Lean.

One researcher and strategist has helped us to understand the people part of the Lean Thinking equation. Ikujiro Nonaka has dedicated his life to understanding how we create and use knowledge in teams and in our organisations.4 Along with his fellow researcher, Hirotaka Takeuchi, he has developed the SECI process. This process is one of the underpinnings of the learning process in Lean.

To help you with your understanding and practice of Lean, you need to know a little more about SECI as it holds some of the key to why Lean works and what you as a Lean Thinking practitioner can do to promote and embed Lean in your teams and place of work.

Think of SECI as a spiral with four sections that feed on each other and each ‘turn’ of the spiral helps the next turn.

Here is an explanation of the sections. Before you start however you need to know a bit more about two of the concepts. These are tacit knowledge and explicit knowledge.5

Tacit knowledge is the stuff we just know and know how to do. It is experience and intuition.

Riding a bike or playing a piece of music are examples of tacit knowledge. They are things that become innate with experience. In the workplace we learn how things work, how to do things, we develop ‘work arounds’ for problems and challenges.

Not everyone knows these things or even knows of them. However, the knowledge is there and is evident in the way things are done. Even in the Army with its focus on training and making things explicit there are still very likely ways of working and processes that are tacit. This does not mean that they are risky or against policy. They are ways that soldiers have figured out how to do things in a ‘lean’ way.

The SECI model shows how both tacit and explicit knowledge can, in different ways, create new knowledge when it is shared. The process of learning can continue to spiral, creating further new knowledge. It is an illustration of how new knowledge emerges when we put knowledge into action.

This knowledge creation and sharing model is one of the foundations of Lean Thinking. The outcome is a capability set that enables the organisation and its teams to do what they need to do to be successful.

These knowledge types are the inputs to the Socialisation-Externalising-Combination-Internalisation (SECI) model. The SECI model is the process by which the knowledge is turned into capability and expertise.

Here are the details of the components of the SECI model.

Adapted from Nomura and Kametsu (1999), p.64.

This spiral of knowledge creation and continuous improvement can occur at many levels of an organisation. It can occur between individuals, whether they are peers, officers and direct reports, or mentors. It can occur within and between teams and barracks. It can occur within the individual. The larger the scope of the spiral the greater the potential impact of the knowledge creation process.

Reflective Activity

We understand that there were many concepts, topics and themes in this section. It also is the foundational section of your learning about Lean and Lean thinking. We believe that for you in your roles you appreciate knowing WHY and HOW the learning and capability system works as well as knowing how to apply your learning.

Numbered divider 1

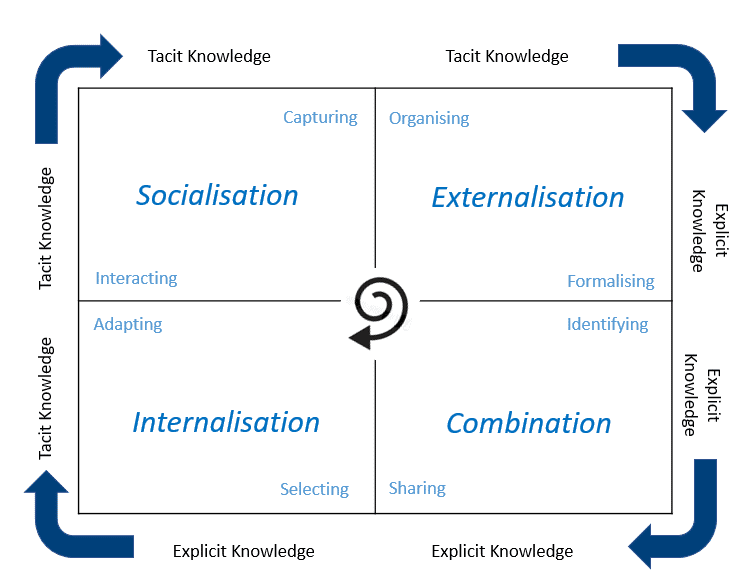

Reread the various pieces of the SECI model and the explanations.

Numbered divider 2

Take the time now to look for a SECI example in your teams, in the Army more generally or perhaps elsewhere in your experiences.

Numbered divider 3

Look for something perhaps that started small or was a spark of something that captured attention and then grew and was shared.

Numbered divider 4

Map the stages in the SECI template and write a short description in each of the quadrants of what happened. Include some details about who shared, how they shared, what happened when they shared. You might also note some of the things that didn’t work so well. What were the blockers that were in the way?

Numbered divider 5

Remember that the Army is one of the Australia’s foremost learning organisations so there will be many examples around you of virtuous learning cycles – you just need to be on a treasure hunt!

References

- Khoshnazar, I. (2019). The Caveats of Applying Lean in Knowledge-Intensive Services with Hierarchy: Evidence from an Emergency Department Southern Illinois University at Edwardsville].

- Herscovici, A. (2018). New development: Lean Thinking in smart cities. Public Money & Management, 38(4), 320-324. https://doi.org/10.1080/09540962.2018.1450924

- Herscovici, A. (2018). New development: Lean Thinking in smart cities. Public Money & Management, 38(4), 320-324. https://doi.org/10.1080/09540962.2018.1450924, p.g. 320.

- Nonaka, I., & Takeuchi, H. (2011). The wise leader. Harvard business review, 89(5), 58-67, 146.

- Peloso, A., & Warren, A. (2020). Strategist. Coach. Strategy as Knowledge in Action. QUT.

- Nonaka, I., Toyama, R., & Konno, N. (2000). SECI, Ba and Leadership: a Unified Model of Dynamic Knowledge Creation. Long range planning, 33, 5-34. https://doi.org/10.1016/S0024-6301(99)00115-6

- Jackson, M. (2006, 09/01). Creative Holism: A Critical Systems Approach to Complex Problem Situations. Systems Research and Behavioral Science, 23, 647-657. https://doi.org/10.1002/sres.799. Page 3.